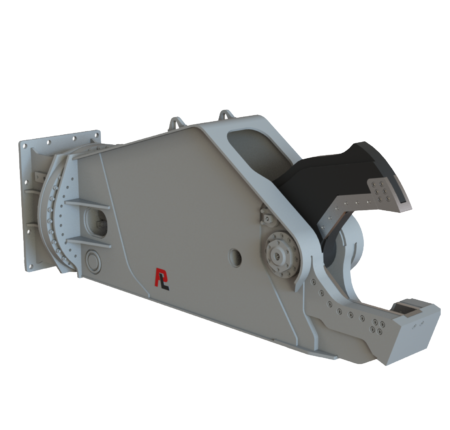

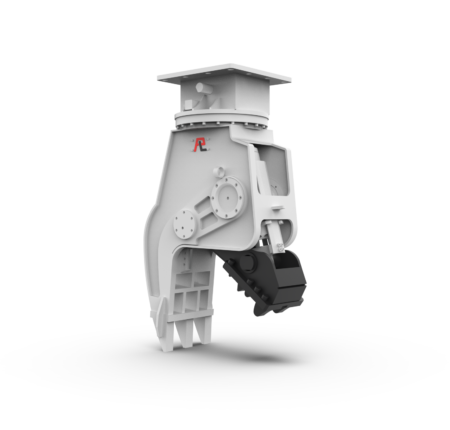

Pulveriser fixed

The fixed pulveriser is suitable for performing secondary demolition work. This includes reducing material from concrete structures and buildings and separating concrete from iron.

Read more- Quick, tailor-made offers!

Strong features

-

Interchangeable gear plate

Welding on the movable jaw is now a thing of the past. The tine plate can be changed quickly and easily, allowing the operator to start work immediately. The tine plate is made of Hardox® wear-resistant steel.

-

High closing force

The Pladdet pulveriser line has an exceptionally high closing force, which means that results are achieved quickly.

-

Jaw opening

The large jaw opening ensures maximum performance.

-

Speed valve

The speed valve regenerates oil for faster cycle time.

Pulveriser fixed

The Pladdet pulverisers are standard fixed models, but the rotatable versions are becoming more and more common. They are also used for primary demolition work, making the purchase of combination shears superfluous. The blades at the back of the pulveriser jaws easily cut through any remaining rebar. The pulveriser has one cylinder and is equipped with a protection that reduces the risk of damage. Suitable for machines from ca. 3 tons up to 100 tons.

Material

Our pulveriser is made of Hardox® wear-resistant steel. The movable jaw is made of reinforced and wear-resistant cast iron. As a result, the pulveriser delivers maximum performance with minimum wear. All fixed pulverisers are also available in a rotatable version.

3-year warranty

Our pulveriser has an exceptional 3-year warranty.

View our product range here used pulvariser fixed and new pulvariser fixed

Have a question? We're glad to make a recommendation!

- Phone +31 (0)115 481 351

- Worldwide +31 (0)115 481 351

- E-mail info@pladdet.nl

Photo gallery

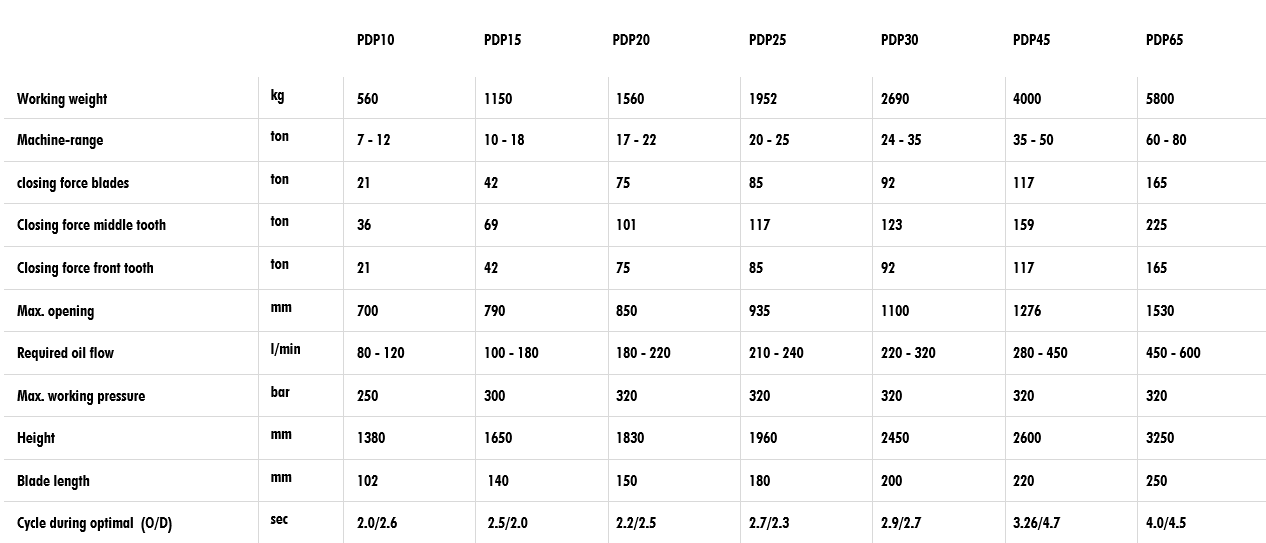

Various models

The Pladdet pulveriser is available in different sizes.