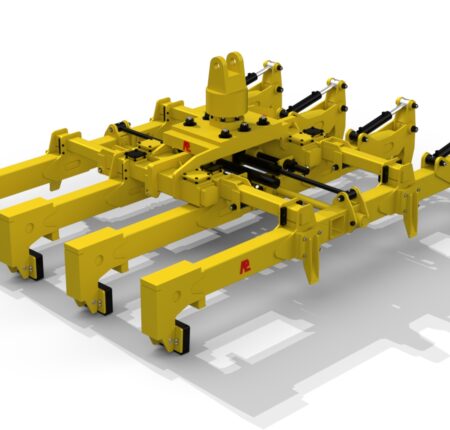

Ballast suction unit

The ballast suction unit is mainly used on railway tracks to suck up loose ballast with the help of air flow.

Read more

- Quick, tailor-made offers!

Strong features

-

Developed for and by railway companies

The Pladdet ballast unit was launched in 2015 as the first model and, in cooperation with our customers, gradually developed into the third model.

-

Low design

Because the doors open on the side, a low construction height is achieved. The unit is also equipped with a side connection so that the quick-change plate can be mounted on the top or the side.

-

Flexibility

The ballast suction unit is supplied with a suction nozzle that can go up and down and can rotate. In addition, the complete unit can also rotate a bit, for instance in order to suck closer to the platform.

Ballast suction unit

How the ballast vacuum cleaner works

A movable suction hose – both hammering and rotating – carries the material with the air flow to the reservoir. Once in the reservoir, the material falls to the bottom by gravity. The airflow continues through the sieve. The sieve is located at the top of the reservoir. The air flow continues through the impeller and the impeller housing, where it continues its way out. The outlet has a coarse filter. Around it is a fine filter.

Spray installation for dry materials

For dry materials, a sprinkler system has been constructed. The water is added to the suction nozzle in the form of fine drops. Thus, it is well mixed in the air flow. By spraying the ballast with water, a considerable dust reduction is achieved. The air flow is pulled through a centrifugal fan. The centrifugal fan is driven by a hydraulic motor.

View our product range here used ballast suction unit and new ballast suction unit

Have a question? We're glad to make a recommendation!

- Phone +31 (0)115 481 351

- Worldwide +31 (0)115 481 351

- E-mail info@pladdet.nl

Photo gallery

Various models

The ballast suction unit is available in one size.